Get Eversa®, a bio solution that drives

business efficiency and flexibility

Use enzymes in your process for higher quality output

As the world moves towards low-carbon fuels, biodiesel is expected to be in high demand. Yet the biodiesel

market is no stranger to turmoil. How will you ensure you plant is profitable when so many factors conspire

against you? Feedstock flexibility is the key!

The current biodiesel process faces a feedstock limitation. But what if that doesn’t have to be the case.

Eversa® is an enzymatic biodiesel process that gives you flexibility in feedstock, simplicity in process and

better quality of product. It’s economical to set up and can be retrofit at low cost to any chemical plant.

All you need to do is switch from chemical processing to Eversa®.

Why switch to Eversa®?

Chemical Processing

- Rigid and stringent, with specific feedstock required. E.g. Low FFA and moisture content required before feeding into transesterification biodiesel plant

- High Capital Expenditure

- A complex process involving multiplesteps, including pre-treatment

- Crude glycerine with impurities like salt and soap

Eversa®

- Flexibility to use a wide range feedstocks with various FFA levels

- Lower Capital Expenditure

- Improve yield by recycling by products, such as fatty matter, and converting the inherent FFA of crude vegetable oil into FAME

- Produces better quality glycerine with higher concentration and little to no impurities

Transform your business today

![]()

Expand your feedstock pool

Gain the flexibility to switch between feedstock according to availability;

price and carbon chain, and take control of your feedstock costs

![]()

Use greener solutions

Produce biodiesel in a process-friendly operation and still obtain salt-free

and minimum soap content glycerine

![]()

Optimise your process

Unlock the true potential of your processing plant, and squeeze every drop

of productivity and profit from your operations

![]()

Stay ahead

Feedstock flexibility gives you the freedom to utilize a wide range of feedstock, minimising your dependency

on conventional feedstock to meet the growing demand for biodiesel

A gamechanger for profitability

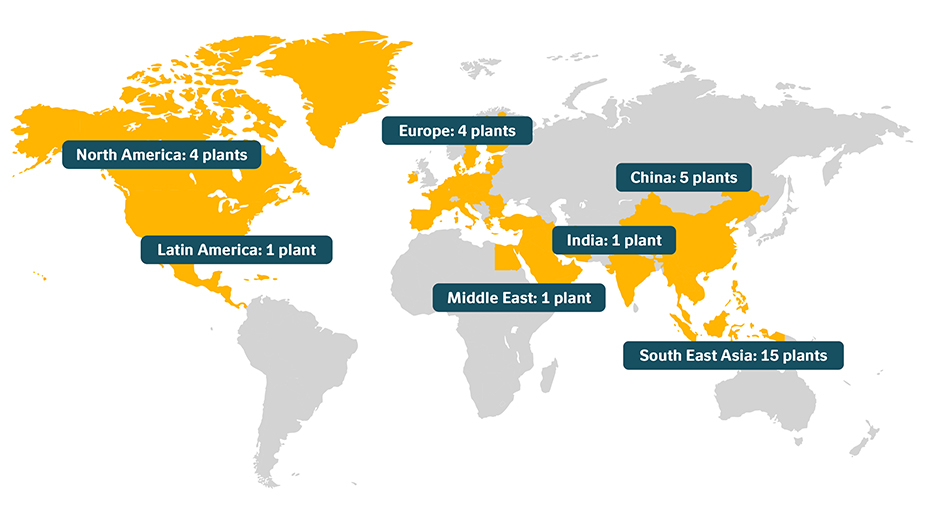

Eversa® Transform 2.0 is used in more than 30 plants worldwide over the last 5 years. It can be deployed in

both greenfield and retrofit units for co-processing or stand-alone applications.

“The Novozymes process is a game changer for the profitability of our plant. We are now able to convert

low-value feedstocks with high acidity to biodiesel that meet the EN biofuels Standards in Europe. The

process requires limited capital expenditure and we were able to implement it by ourselves

by retro-fitting an existing facility.”

Ismaeil Zaher, Technical Director,

Biodiesel Misr, Egypt

“Novozymes’ process is a cost-efficient and proven alternative for converting secondary oils like fatty acid

distillates, DGS corn oil, UCO and animal fats into biodiesel with relatively low capital expenditure by

retrofitting a plant.”

Marc Kellens, Group Director of Technology,

Desmet Ballestra, Belgium

“Novozymes’ enzyme-based transesterification process allows milder processing condition for biodiesel

producers, which makes the industry safer and more sustainable by using less energy as well as generating

better quality glycerine. The process simplicity of enzymatic solution also translates to competitive Capital Expenditure

investment and fast implementation. ”

Henry Yong, Managing Director,

Oiltek , Malaysia

Webinar :

Don't let profit go to waste

staying ahead of rising biodiesel

feedstock prices

With a paradigm-shifting enzyme solution that is fast and inexpensive to implement, Novozymes

is the best partner to stay ahead of the biodiesel game.

The Oils & Fats Asia Pacific center of excellence located in Kuala Lumpur, Malaysia not only

contains state of the art laboratories feature equipment, we also have a team of highly skilled

and experience technical expert to support and drive business impact together with our

customers.

In the video we provide you an overview of our Oils & Fats centre of excellence capability and

illustration of enzymatic biodiesel process.

Yes, I want to learn more.

Please contact me.

About Novozymes

Biological answers for a growing world

Novozymes is a global biotech company with 6,000 employees, production around the world, and

headquarters in Denmark. Since the 1940s we’ve used enzymes to unlock our customers’ growth potential.

When you get in touch with us, you’ll see we have plenty of expertise in biodiesel production. In an industry

driven by fine margins and growing demands, we believe you shouldn’t settle for just good enough

solutions. It’s time to go beyond accepted limits. It’s time to expect more.