Viscosity Reduction in Fermentation

Viscosity Reduction in Fermentation

Viscosity has a major impact on heat exchange operations such as mash cooking, mash cooling, fermentation cooling, distillation, evaporation, and drying. High viscosity results in poor heat exchange and necessitates the design of larger heat exchange surfaces.

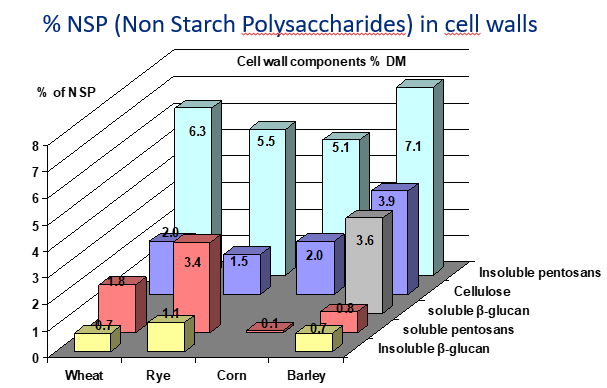

When considering viscosity reduction, attention normally focuses on the breakdown of starch, since this is the major component of grains and can cause extreme viscosity if not addressed. Most distilleries have had the unfortunate occasion to have to deal with the effects of a loss of liquefaction enzyme, or a pH controller gone awry. It can spoil one’s entire day, to put it lightly! However, today’s alpha amylases are quite robust and enable the processing of high starch concentrations. There remains, however, another source of viscosity that has nothing whatsoever to do with starch. Figure 1 shows the composition of several of the small cereal grains. Note that it is only the soluble NSP (non-starch polymers) that create viscosity. It can be seen that corn (maize) has almost no soluble NSP. Hence, the viscosity in corn mashes is only due to starch, not NSP.

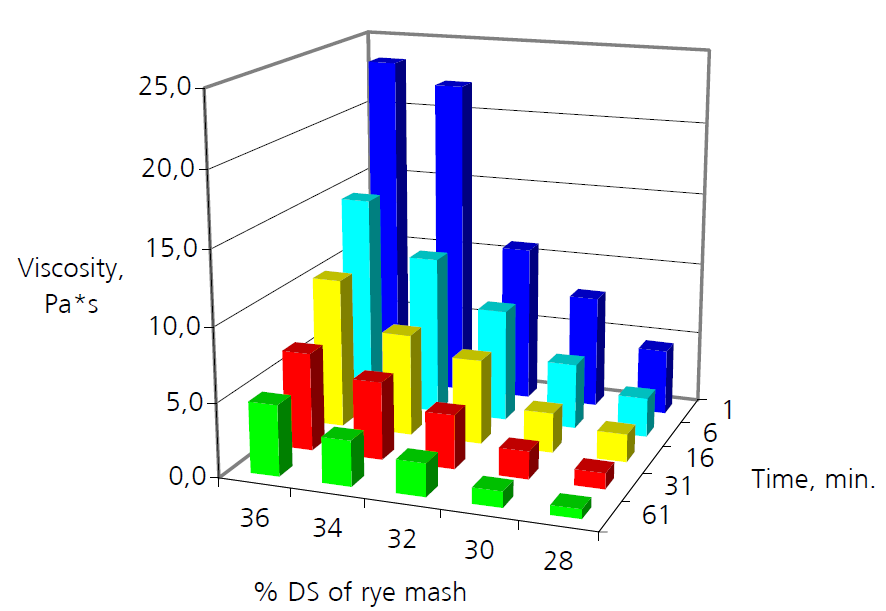

Producing distilled spirits from cereal grains such as wheat, barley, and rye presents quite a challenge. NSP such as beta-glucans, pentosans, and arabinoxylans create high viscosity, which has a negative impact on downstream processes. Rye, which has recently seen a significant increase in use, contains several different NSP, so it requires a complex blend of enzymes known as Viscoferm® in order to run efficient fermentations and distillation. Figure 2 (Viscosity of rye mash treated with 0.3 kg / t DS Viscoferm® at pH 6.3, 50ºC and shear rate 10/s ) shows that when Viscoferm is used, the mash viscosity at 36% DS (60 minutes treatment) is approximately the same as that of untreated mash at 28% DS.

High viscosity reduces the dry substance level which can be handled in liquefaction and fermentation, increasing energy and water consumption and lowering ethanol yield. NSP reduce the efficiency of separation, evaporation, and heat exchange. The use of viscosity-reducing products such as Viscoferm® give you higher ethanol production capacity and lower operating costs. Novozymes offers solutions for reducing viscosity for these grains, broken rice, cassava, and most other fermentation feedstocks you are likely to utilize. By applying the correct viscosity-reducing enzymes for your feedstock, you gain flexibility in the choice of feedstocks and improve your ability to process at higher dry substance levels.

Author: Larry Peckous