Identifying inoculant contamination

What you'll learn:

Pelleting is a normal occurrence in inoculants

Contamination, although rare, may happen and cause the inoculant to be ineffective

Contaminated bladders should not be used

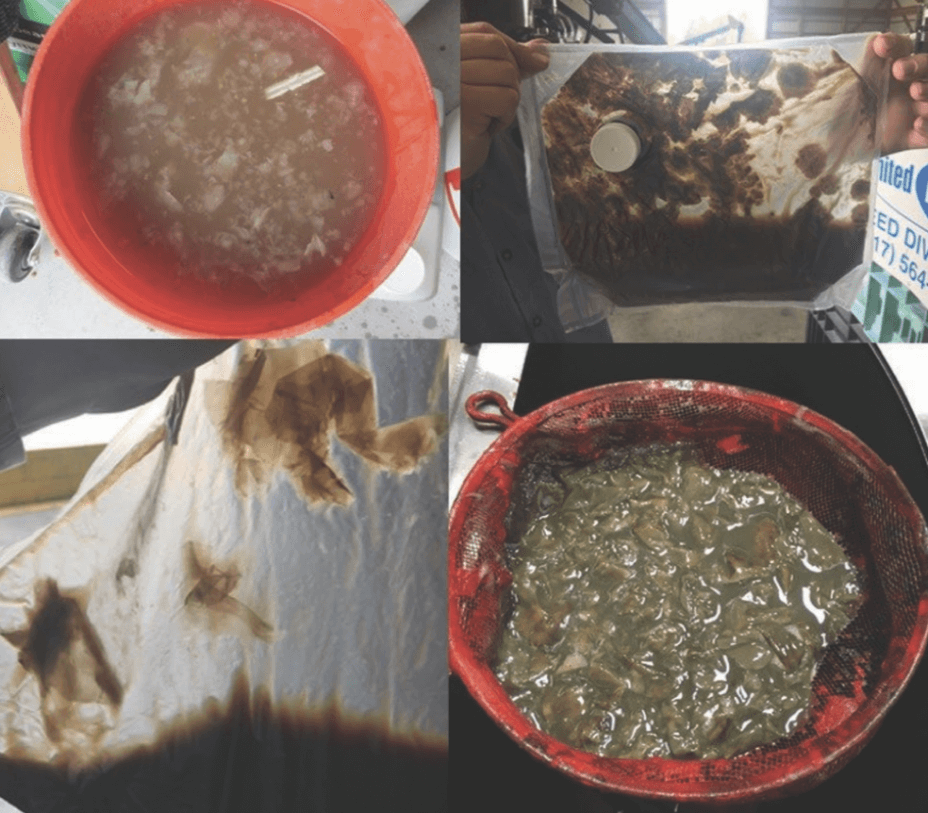

Normal pelleting vs. contamination

Pelleting is a normal occurrence and can be more pronounced in concentrated products such as Optimize® XC and Tag Team® LCO XC technologies. Pelleting is the result of bacterial cells, insoluble fermentation ingredients and/or other contributing factors settling out of the solution into masses that can be seen in the bladder lying on the film. Pelleting should not be a reason for concern and the pellets should resuspend back into the solution with very little effort. Following package directions and gently shaking the bladder should be enough to achieve suspension.

Even with adhering to the highest operational procedures, contamination may occasionally occur. Contamination may happen in different ways. One example is microscopic holes that may be created at pinch points of the bladder during filling. These holes allow for contaminants to enter the nutrient-rich medium.

Odor and visual cues are two ways to identify a contaminated bladder. A distinct odor is often the first thing noticed. A contaminated inoculant will have a very off smell, it can be rank, smell like ammonia or be very sharp.

Some masses in a contaminated bladder, unlike pelleting, will not easily go back into suspension. The masses may look like sheets or bits of tissue floating in the bladder. If a fungal contamination is to blame, the problem may be more noticeable with large masses of semisolids being present in the bladder.

What to do if you suspect contamination

If contamination is suspected, you should contact the distributor through which you purchased the product. Your distributor will be the most efficient source for replacement product to minimize treatment interruptions. The distributor will work directly with Novozymes® BioAg.

Summary

Pelleting is a normal occurrence in inoculants but floating masses or masses stuck to the bladder film are not. If after following label directions and resuspension methods you are still unsure if contamination may have occurred, refrain from using the product. Contaminants may render the product ineffective and they can block screens in treaters. Upon opening the bladder, if inoculant emits an off smell or rank odor, contamination may have occurred. Contaminated products should not be used. Reach out to your distributor if you believe you have a contaminated product.

Partner with us

Your innovation partner

Our commitment to innovation has helped us develop the world’s leading microbial inoculant, biostimulant and biocontrol solutions portfolio.

By partnering with us, you could make that commitment work for your business.

- Investment, with around 14% of our revenue going towards research and development

- Vertical integration from discovery to production. That leads to close cooperation between our R&D and commercial teams

- A global presence, with fermentation facilities across the globe ensuring that you can trust us to deliver on time

- World-leading formulation technologies that promote homogeneity and stability in our products