BioInnovate your beamhouse with enzymes

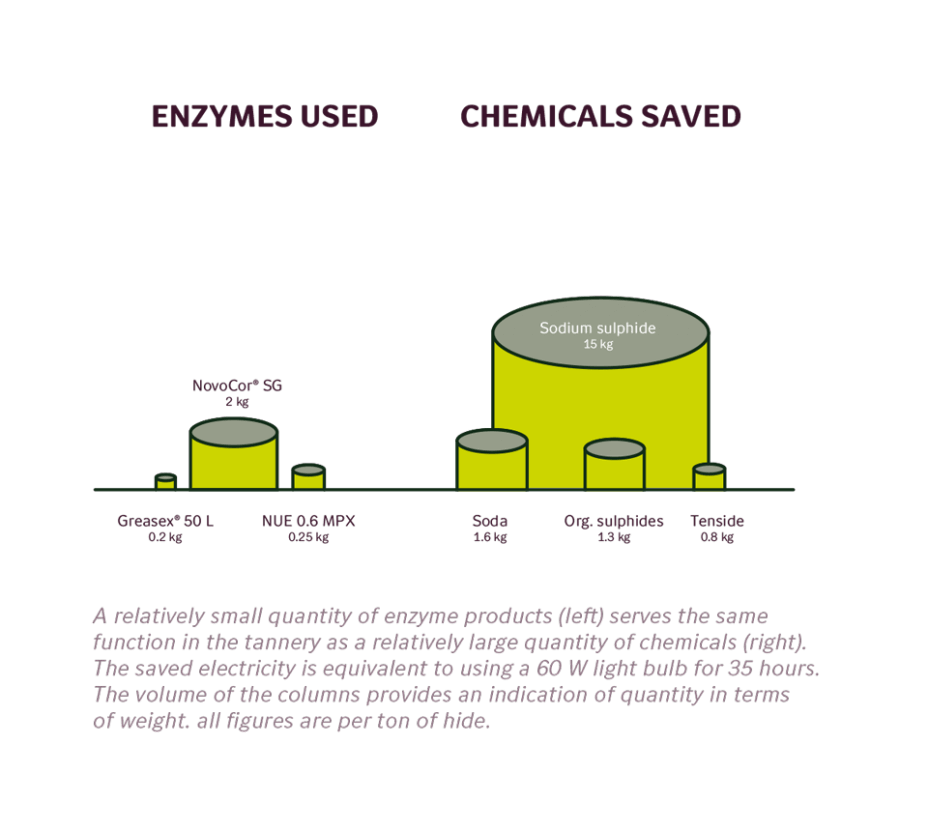

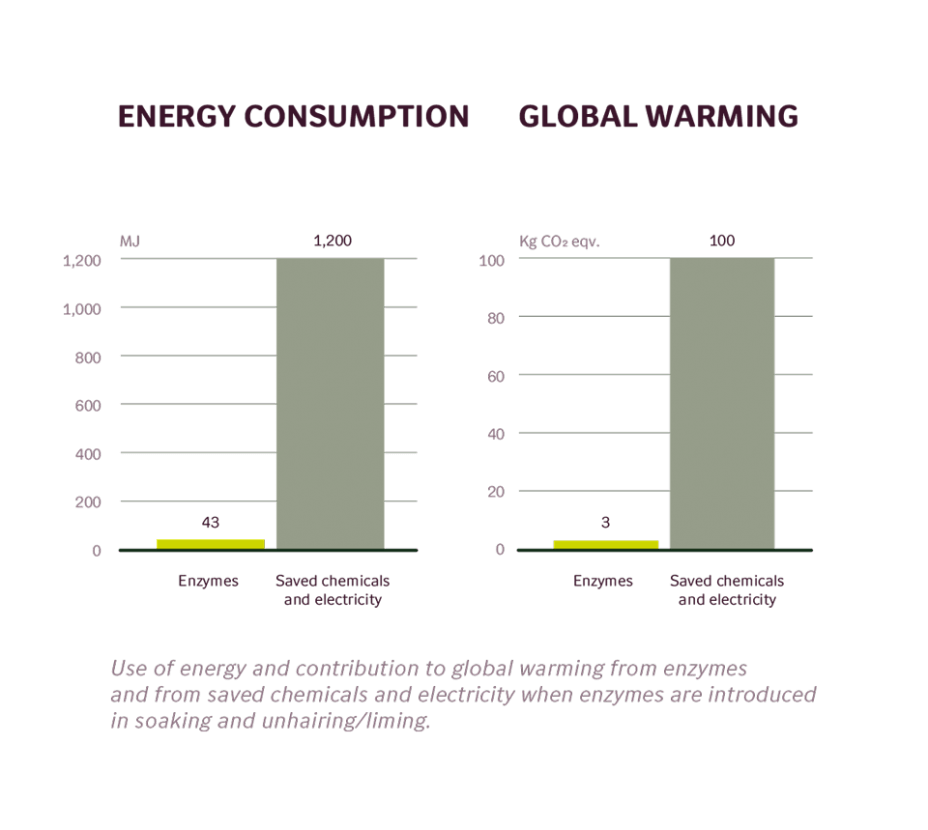

Enzymes are the biotechnological alternative to chemical leather manufacturing and can in many processes save time and energy. Meanwhile, enzymes reduce or eliminate the need for tensides, solvents or other demanding methods in the tannery. For more than 50 years Novozymes has been innovating the leather industry with enzymatic solutions for soaking, liming, bating, re-bating, and degreasing

Replacing chemicals with biodegradable enzymes can reduce dependency on price-fluctuating petrochemical technology, and can give tanners a stable foundation for costs – all with a sustainable touch since enzymes:

Reduce pollution from harsh chemicals

Make a number of chemicals superfluous

Make side streams more clean

Save energy by lowering processing temperature and shortening process time

Improve working environment in leather production

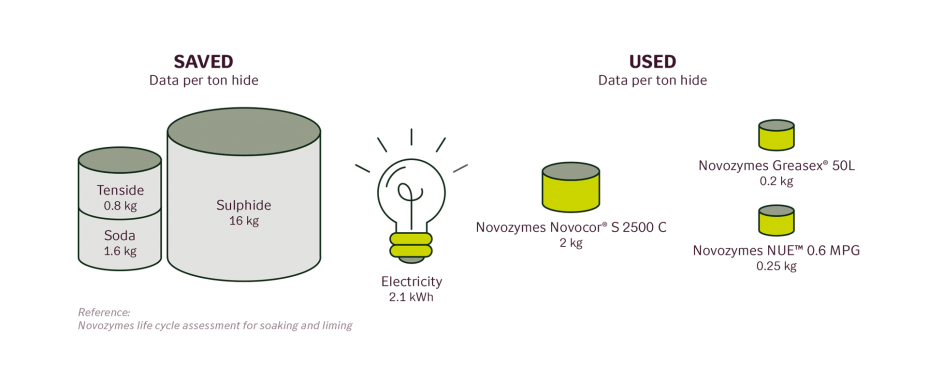

Used and saved when enzymes are introduced in soaking and liming

Apart from being the sustainable alternative to traditional processing, Novozymes’ enzymatic solutions can make processing easier and significantly improve the quality of the leather.

Soaking:

- Improved rewetting uniformity

- Easier removal of dirt and soluble proteins

Liming:

- Facilitates excellent opening of the fiber

- Ensures good scud loosening and reduced swelling

Bating:

- Clean, pale and uniform pelt

- Increased tear strength

- Increased softness

Re-bating:

- Removes wrinkles

- Softer leather

- Uniform dyeing

Degreasing:

- Homogeneous degreasing

- Uniform dyeing and dye uptake

- Increased tear/tensile strength in the finished leather