Case study: Denmark’s largest wastewater treatment company uses BioSec®

After BIOFOS ran three independent field trials at their municipal wastewater plant in Avedøre, they chose to use BioSec® on an ongoing basis.

About Biofos

Denmark’s largest wastewater treatment company

Clean 104 million m3 wastewater/year

Serve 1.2 million people

Run three treatment plants in Denmark

Incinerate 24,000+ tons sludge dry solids per year

Generate electricity, biogas and district heating

Field trials lead to ongoing BioSec® use

The results of BIOFOS’ three independent field trials of BioSec® in 2017 and 2018 were convincing:

Cake dryness after mechanical dewatering increased by 1.5-1.6 %-points

Polymer consumption reduced by up to 15% (9.4 kg/t TS to 8.3 kg/t TS)

Reject water quality improved (lower TSS, COD)

So convincing, in fact, that BIOFOS has continuously been using BioSec® since April 2019. And nearly a year later, the Danish wastewater leader reported these results:

Up to 2 %-point improvement of cake dryness after dewatering

15% reduction in polymer consumption

Centrifuges running at lower speed (energy audit in progress)

"We have never seen such clean reject water before"

The plant treats mainly municipal wastewater

The setup at BIOFOS Avedøre is typical of most municipal wastewater facilities. BIOFOS Avedøre pre-thickens primary and secondary (excess activated) sludges in primary and secondary clarifiers. Then they treat and stabilize mixed primary and waste-activated sludge in four parallel anaerobic digesters.

Each egg-shaped digester operates as a one-stage reactor at mesophilic conditions with approximately 25 days hydraulic retention time (HRT). Then they pump digested sludge (800-1000 m3 per day) into four equalization holding tanks. These open basins use aeration for mixing with an HRT of 8-24 hours.

Dewatering takes place in one of three centrifuge decanters, operated 24/7. The plant incinerates the biosolids generated on site.

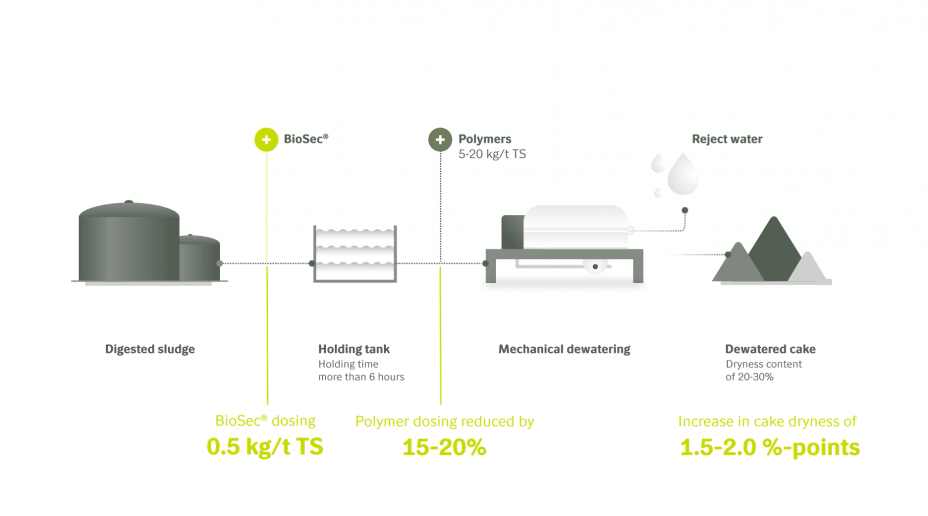

Adding a small dose of BioSec® to the digested sludge can help increase cake dryness and save on polymers

A plug-and-play solution

In the trials, BIOFOS doses BioSec® into the sludge stream between the anaerobic digester and the post-digestion sludge holding tanks. They allowed 8-24 hours of enzyme reaction time with the digestate before dewatering.

"Implementation and dosing start-up was both quick and easy"

One dose of BioSec® was tested in all three trials (0.25 kg BioSec®P and 0.25 kg BioSec®C/t TS; total dosage 0.5 kg/t TS).

Conditions during the field trials

BIOFOS evaluated the impact on dewatering of digested sludge by centrifuge based on:

Cake dryness after mechanical dewatering

Polymer consumption

Quality of reject water

They monitored the following operating parameters during both test and reference periods:

Digested sludge flow to centrifuges

Total solids flow to centrifuges

Ratio of primary and secondary sludge fed to digestion

Digestion performance

Centrifuge settings were constant throughout. BIOFOS also monitored parameters known to influence sludge dewatering performance and took them into consideration during data evaluation. These include load of primary and secondary sludges to anaerobic digestion, anaerobic digestion performance, sludge load and flow to the centrifuge.

Ready to try it out?

Novozymes BioSec® is a liquid solution containing two different, proprietary enzymes – BioSec®P and BioSec®C. Novozymes has specifically developed these enzymes to condition anaerobically digested sludge and improve dewaterability.

BioSec® is used to increase sludge cake dryness and decrease flocculant consumption during mechanical dewatering of digested sludge.