Scientific Articles about Brewing Enzymes

If you are interested in learning more about brewing enzymes in detail, you’ve come to the right place! Below is a compilation of scientific articles and studies around brewing enzymes and testing of some of Novozymes’ products. Learn more about alternatives to malt in brewing, unmalted oats, brewing with raw barley, using 100% unmalted grains and more!

“Using Unmalted Barley for Brewing”

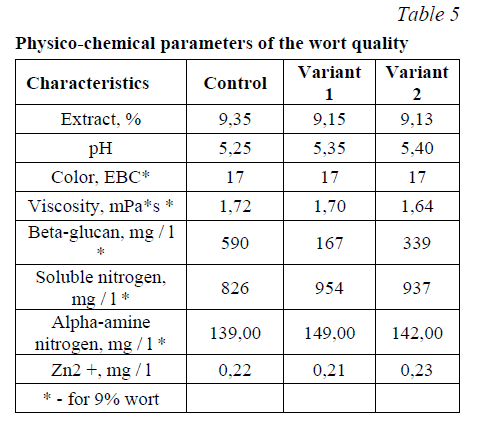

Aim of this study was to compare worts and beers made with 60% malted barley and 40% raw, unmalted barley. Two mashing types were used - infusion and decoction. Both worts were made using Ultraflo enzyme. Control was 85% malted and 15% unmalted barley. Results showed that both variants with 40% raw barley and Ultraflo had similar parameters that control sample. Yet they had better filtration speed and yield. The main difference was lower content of beta-glucans, which would be desirable as they can cause problems with beer filtration. It was concluded that “Using big amount of unmalted grits together with external enzymes gives brewers an opportunity to receive wort/beer in the same composition and quality like high-quality wort/beer using only malt.”

“Alternatives to malt in brewing”

Article focuses on the potential of using alternatives to malt in brewing, how to use them, what are the benefits and drawbacks. Authors conclude that adjuncts can reduce processing costs, also they can “help save energy and water, by removing the need for kilning, germination and steeping processes. As a consequence, the carbon footprint of beer production may be diminished.” Using grains with low protein content can produce beer with improved colloidal stability, and decrease in flavour staling precursors. Furthermore “use of unmalted raw materials, changes can be made to the flavour profiles of beers. This gives brewers the ability to develop final products with new sensory characteristics.” On the other hand “low levels of soluble proteins can result in less full-bodied beer and lower head retention”. Yet the biggest challenges, that brewers have to face when using unmalted adjuncts, are technical difficulties, such as “insufficient quantities of enzymes from the malt to perform saccharification of starch or to degrade gums and hemicellulose, causing filtration problems” and “the low content of assimilable nitrogenous compounds available for the yeast”. Fortunately “Most problems connected with the ineffective breakdown of polymers from raw grains can be overcome, however, by the application of exogenous enzymes.”

“Malted and unmalted oats in brewing”

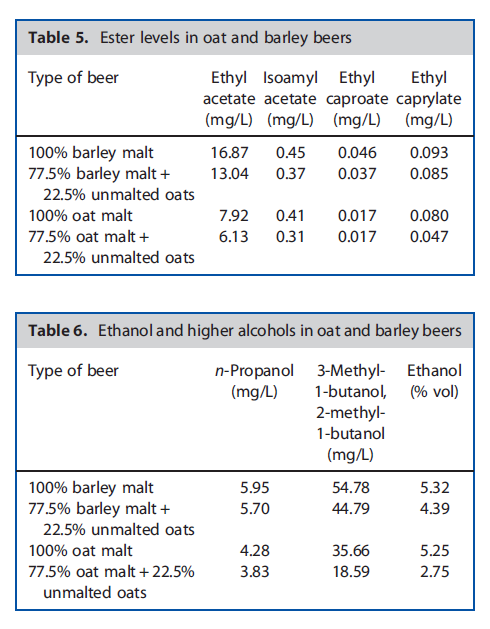

The aim of this study was to test oats, as an alternative for barley in beer production, as oats does not contain gluten, and could be used for gluten free beer. Also it contributes to novel sensory properties, which could be desirable. For this purpose test batches made of both malted and unmalted oats were made, with barley malt wort as a control. Wort filtration parameters were analysed with and without enzymes. Extract content, colour, pH, viscosity, free amino nitrogen in wort were measured, then it was fermented, and finally ester levels and alcohol were measured in finished beer. Authors have found that “both the use of oat malt and the addition of unmalted oats prolonged the filtration time and produced a smaller final volume of filtrate”, as well as decreased content of free amino acids. Results showed that “The use of oat adjunct in the production of barley beer can give a more delicate taste, as a result of a lower content of higher alcohols and a more diversified amino acid profile”, which could be desirable. However, because of difficulties arising from the use of oats in brewing “The use of enzymes is recommended when a high proportion of oats is added to the mash (such as 22.5% or more). Enzymes contribute to increasing the extract content and the rate of filtration, and to producing a higher volume of wort.”

“Brewing with malted barley or raw barley: what makes the difference in the processes?”

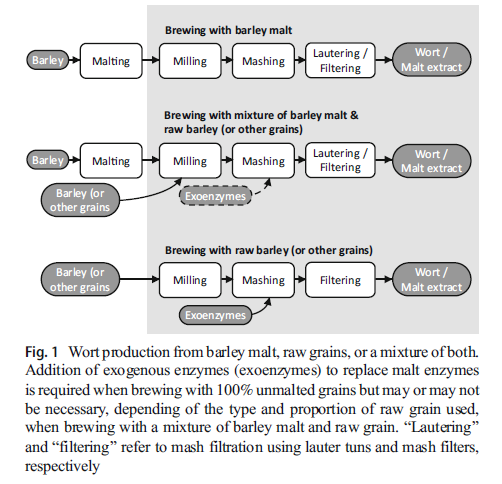

This review focuses on modifications of traditional brewing processes, necessary when using unmalted grains. Using unmalted grains has three benefits: cost reduction, decrease of CO2 emission, and producing “innovative beers with desired features to meet the demands of consumers.” Yet without malting process there are not enough enzymes in the wort made with raw barley in which “the only enzymes present in adequate amounts are exoproteases and β-amylases.”. If raw barley is used to replace a minority of malted barley, then enzymes from malt should be enough to ensure proper mash, but “When using more than 50% raw to malted barley, it is recommended to use a more complete mix of enzymes to replace those normally found in malted barley.”.

“Effect of unmalted oats (Avena sativa L.) on the quality of high‑gravity mashes and worts without or with exogenous enzyme addition”

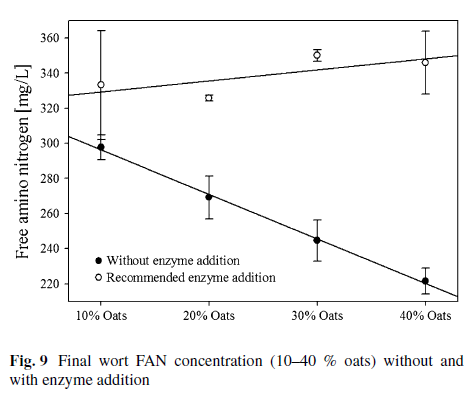

Impact of adding 10-40% of unmalted oats to high gravity mash was tested, with and without adding enzyme mix Ondea Pro. Authors found that “Using up to 20 % oat adjunct had no or little effect on the filtration performance of mashes/worts, whereas the use of 30 and 40 % oats considerably increased filtration times”. Fortunately “the addition of exogenous enzymes to mashes containing 30/40 % unmalted oats clearly improved the filterability of final worts by 34/41 %.”. High levels of unmalted oats reduced free amino nitrogen concentration, even below recommended values for high gravity worts. “The application of Ondea® Pro (2.0 g/kg oats) containing endoprotease and lipase amongst others significantly increased the FAN concentration in final worts by 21.2–55.9 %”. As expected “The use of Ondea® Pro as recommended also significantly enhanced the extract content of final worts produced with 20 % or more oats by up to 0.6 % w/w”. High percentage of unmalted oats significantly increased pH of wort, up to 5,89 at the mash out. Recommended pH value of mash is 5,5 - 5,6, and maintaining its proper value benefits protein degradation, viscosity, lautering and filtration rates, wort color, and attenuation. “applying Ondea® Pro (2.0 g/kg oats) significantly reducing the final wort pH (20 °C) from 5.80 to 5.52 (10 % oats) and from 5.89 to 5.63 (40 % oats), respectively”. It was concluded that Ondea Pro is highly recommended in worts with 30% or more unmalted oats, as it has a positive impact on numerous wort parameters.

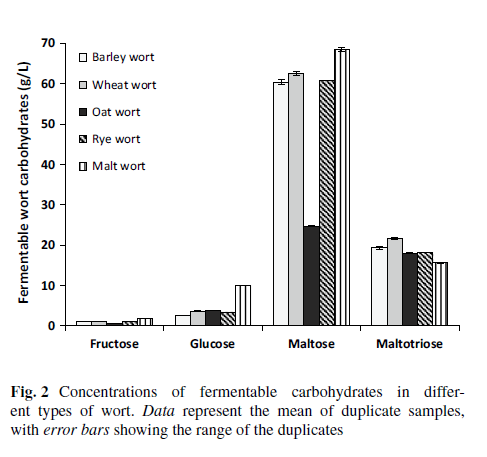

“Brewing with 100 % unmalted grains: barley, wheat, oat and rye”

Aim of this study was to investigate the potential of 100% unmalted barley, wheat, oat and rye, in comparison with 100% barley malt wort. Unmalted grains worts were made using Ondea Pro enzyme mix. Worts made with unmalted grains had similar gravity than wort made with malt, and with the exception of oat similar fermentable carbohydrates concentration as well. Free amino nitrogen content was significantly lower in unmalted grains worts, that it was in malted barley malt, and as authors suggest “a combination of an additional protein rest and increased levels of Ondea® Pro or other enzymes should be investigated in future work for improving FAN for brewing with 100 % unmalted grains.” Beers made from unmalted worts had lower degree of fermentation, than beer made from malted barley, with oat beer having the highest residual gravity. That corresponds to results of tasting, in which oat beer had a much different flavour profile, than beers made with barley, rye, wheat and malt. “In general, there is a decrease in the levels of colour, brightness, higher alcohols and esters in beers produced from unmalted grains than in the beer produced from malt.”

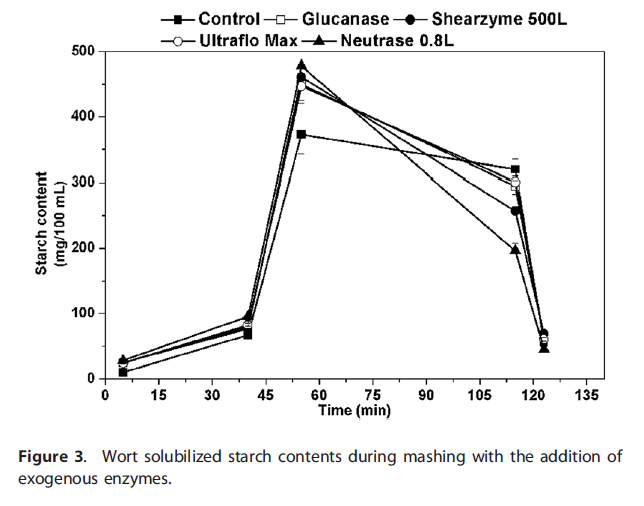

“The influence of proteolytic and cytolytic enzymes on starch degradation during mashing“

Starch degradation during mashing is a key stage during beer production. It determines the amount and composition of sugars in the wort, and therefore alcohol content, mouthfeel and flavour balance of beer. Aim of this study was to determine how exogenous enzymes could improve the starch degradation process. Number of enzymes were used, and their activity measured, as well as starch content during mashing and wort sugar profile. Results showed that adding enzymes to mash increases starch content, which is due to enzymatic breakdown of cell walls. “With the exception of protease, masking of starch by residual cell wall would be another obstacle for release of starch during mashing and solved by the use of exogenous enzymes, which can strip away the glucan and xylan and release the trapped starch.” This activity of exogenous enzymes also increase activity of malt enzymes - “Ultraflo Max, which contained β-glucanase and xylanase, significantly increased the maximal activities of α-amylase, β-amylase and limit dextrinase by 18, 33 and 23% respectively, compared with the control”. As more starch was available for enzymatic digestion, more fermentable sugars were obtained, compared to control, resulting in higher efficiency of brewhouse.

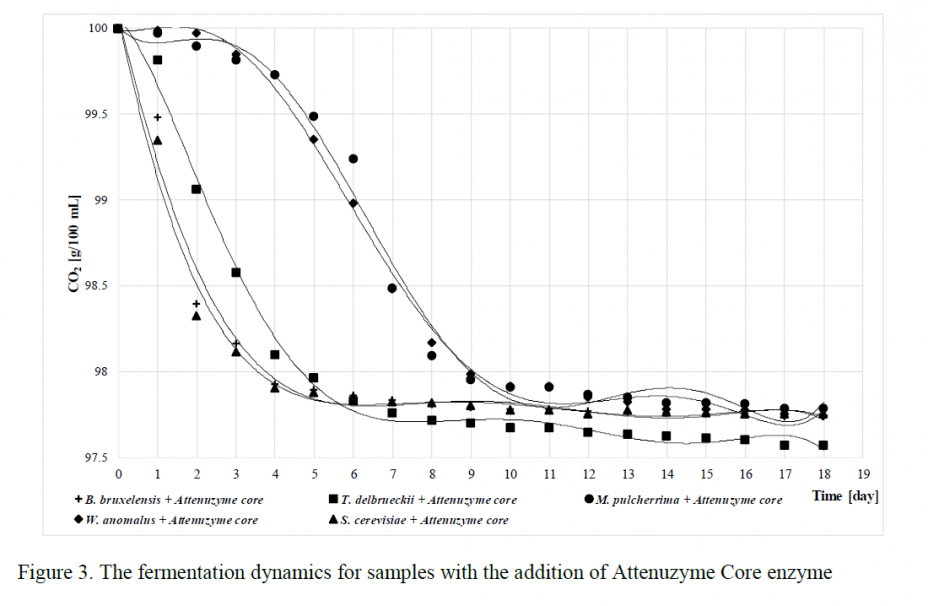

“How non-Saccharomyces yeast could be used for production of new types of beer, with aid of Attenuzyme Core“

Objective of this study was to test the potential of non-Saccharomyces yeast for beer production. “The production of beer with different sensory features is among the most promising advantages of using non-Saccharomyces yeast.” Yet some of those yeast have a long adaptation time, and although the final gravity was roughly the same for Saccharomyces and non-Saccharomyces yeast, some of the latter needed twice as much time to ferment, compared to standard brewing yeast. Using Attenuzyme Core resulted in rapid acceleration of fermentation, and significantly greater alcohol content. Therefore, enzymes could be used to aid fermentation with novel, non-Saccharomyces yeast for producing new types of beer.

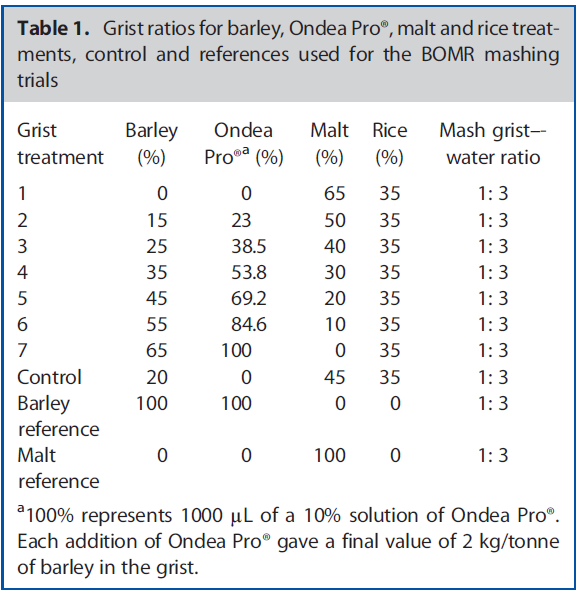

“Comparison of the impact on the performance of small-scale mashing with different proportions of unmalted barley, Ondea Pro®, malt and rice“

Aim of this study was to determine optimal combinations of rice, barley and malt, when using enzyme complex Ondea Pro. “In South Asia rice is the most commonly used adjunct, and ratios of 30-50% in the grist are common in many countries”. Unmalted barley can be an alternative to malted barley, as it is cheaper, requires less energy and water to produce. Furthermore “brewing with enzymes and up to 50% barley produced a beer with increased anti-oxidative potential, good extract and attenuation levels. They also reported that lower FAN levels in wort and beer could lead to less Strecker aldehyde production during beer aging.” Various proportions of barley malt and unmalted barley were tested, with 35% addition of rice, and with 100% malt and 100% unmalted barley worts as references. Through examination of several wort parameters, especially wort extract, fermentability and FAN it was concluded that optimal barley level is 45-55%.

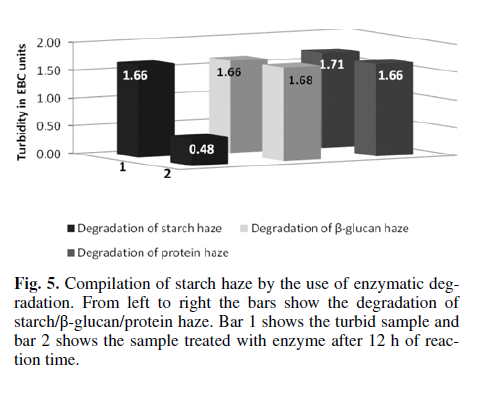

“Turbidity and Haze Formation in Beer – Insights and Overview“

Haziness is considered to be an important problem in classic beer production. Yet in modern, new england style ipa haziness is considered as an important, and desirable trait. In both cases it would be good to know what causes haziness and how to act against it, or how to promote it. In this study three enzymes were chosen - pepsin for degradation of proteins, amyloglucosidase for degradation of dextrins and starch, and Ultraflo Max for degradation of beta-glucans. Results have shown that enzymatic degradation of proteins and starches can reduce haziness. No significant reduction of haze was observed in samples treated with Ultraflo Max, which indicates that this enzyme could be use for hazy ipa without decreasing haziness.

Interested in testing the products yourself?

Read more about the products investigated in the articles, or explore our other brewing enzymes products.